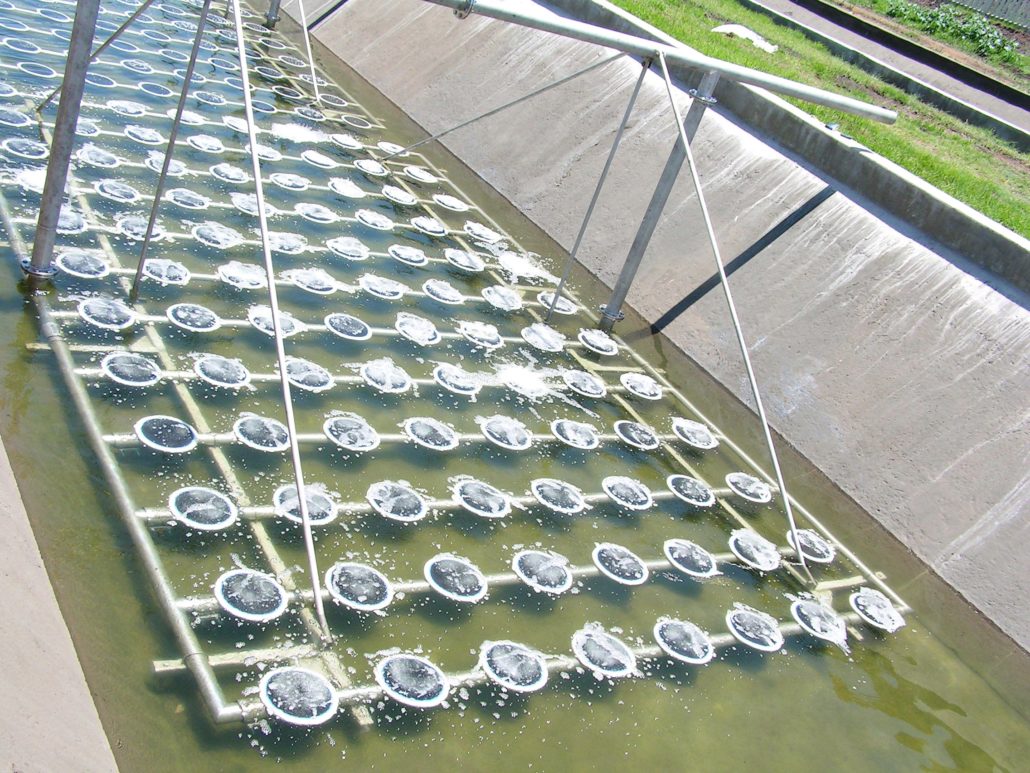

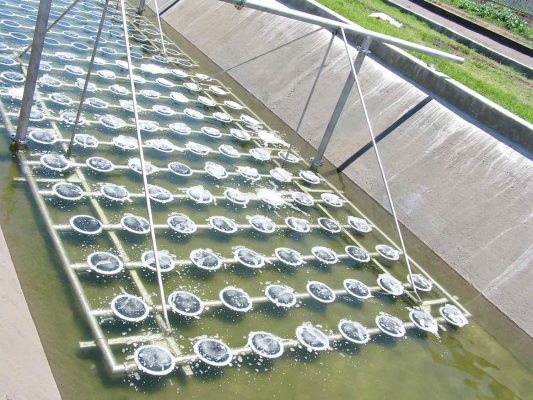

Fine bubble aeration is a subsurface form of diffusion in which air is introduced in the form of very small bubbles in order to enhance the treatment process of wastewater. Air flows through a pipe into diffusers located at the bottom of a tank. These air diffusers have numerous small openings, known as pores, which enable air flow through the wastewater in the tank.

The air diffusers are located on the floor of an aeration basin, fixed to horizontal air headers which are evenly spaced along the floor of the tank zones. The air headers are connected to an air distribution pipe system which receives pressurized air from the air mains, supplied by air blowers. Compressed air from the header enters through the holes in the orifice bolt situated under the diffuser disc, and then proceeds to pass through a specialized membrane. The membrane breaks up the air into microscopic bubbles and disperses it evenly over the whole volume of the aeration zone. As the bubbles rise to the surface, oxygen is transferred via diffusion into the liquor solution.

Applications:

- Water treatment plants

- Wastewater treatment plants

- Treatment of landfill leachate

- Wastewater ozone diffusion

- Oxygenation for sludge stabilization

- Aeration of streams and fish ponds

- Mining industry

- Food & beverage