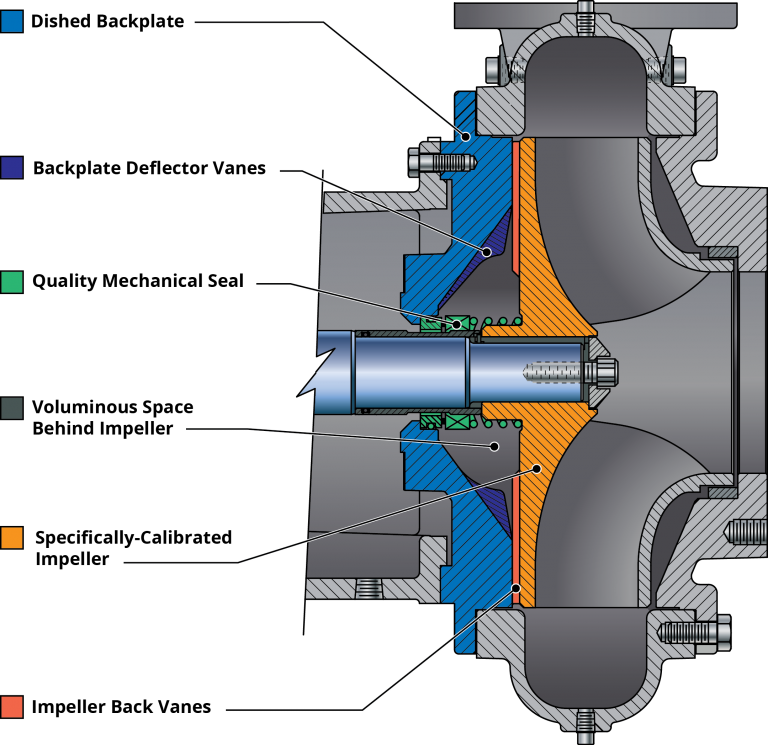

Cycloseal®:

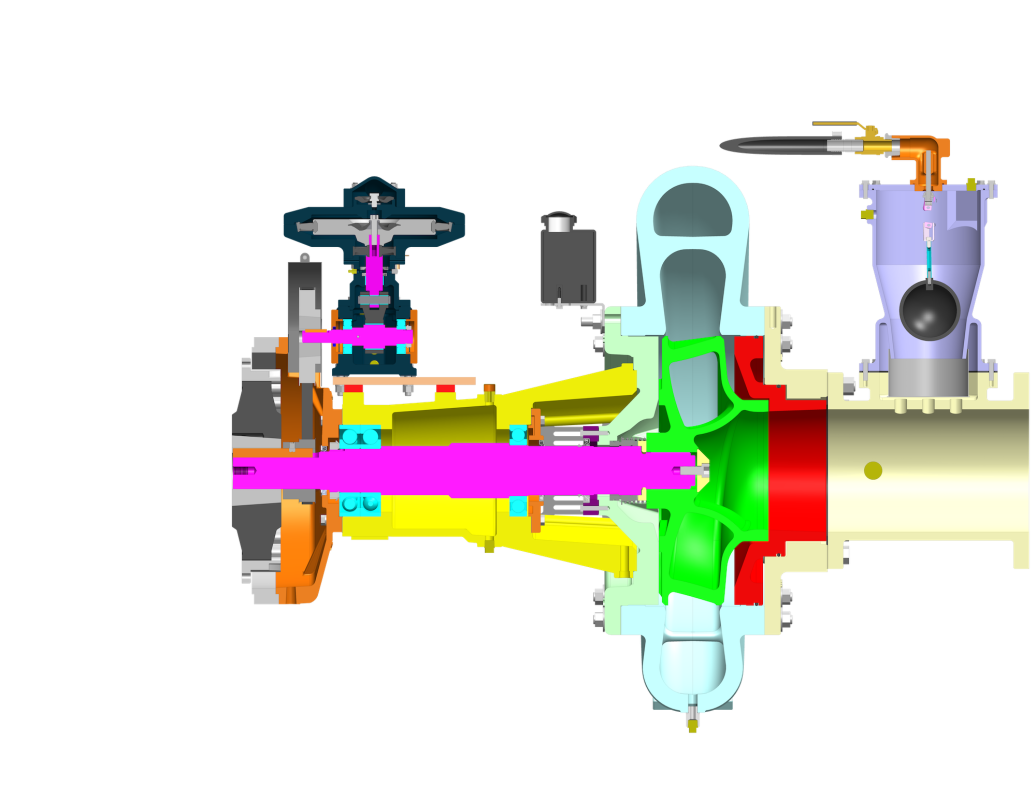

Cornell’s patented Cycloseal® design consists of a single mechanical seal with a dished backplate with stationary deflector vanes, which combined with specially designed impeller back-vanes, create pressure gradients that removes solids and entrained gases away from the seal faces. This translates in substantially longer mechanical seal service life. Cycloseal® design does not require external flush line and thus eliminates the need for a water flush line.

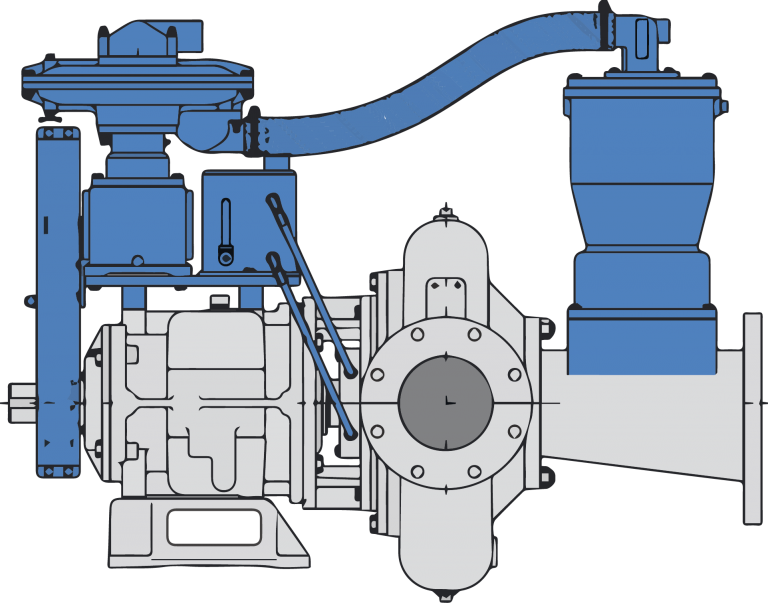

Redi-Prime®:

Most of Cornell’s pumps can be fitted with Redi-Prime®, a automatic vacuum-assisted priming system. Their Redi-Prime® system is offered with a high-capacity diaphragm pump for short priming times, and by using a positive sealing float box, there is no water carry-over to the exterior on the pump, which allows pumping of hazardous fluids such as wastewater or hazardous fluids. It provides automatic re-priming should the pump lose prime.

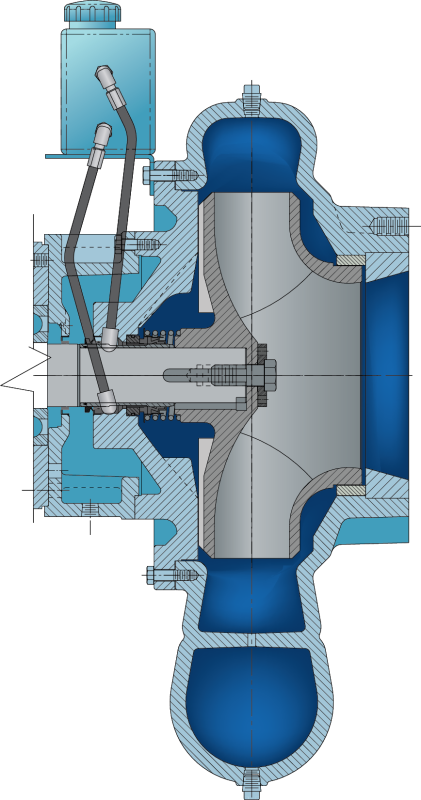

Run-Dry™:

Cornell’s Run-Dry™ option is available to all Cycloseal-fitted pumps where there is a possibility of the pump operating in a dry condition. The Run-Dry™ system consists of an external oil reservoir and an auxiliary gland that keeps the mechanical seal faces lubricated and cooled during priming, re-priming, or stand-by operation. Cornell pumps fitted with Run-Dry™ can operate for hours on end without damaging the mechanical seal.

Co-Pilot®:

Cornell pumps are available with Co-Pilot®, which is a proprietary pump monitoring system which keeps track of the pumps vibration levels, temperature, and GPS location at its basic feature package. Other instrumentation may be integrated to the Co-Pilot® to monitor for flow, pressure, or for remote operation. Co-Pilot® is an IIOT device which can be connected via Wi-Fi or GSM networks to provide monitoring and alerts from anywhere in the world.

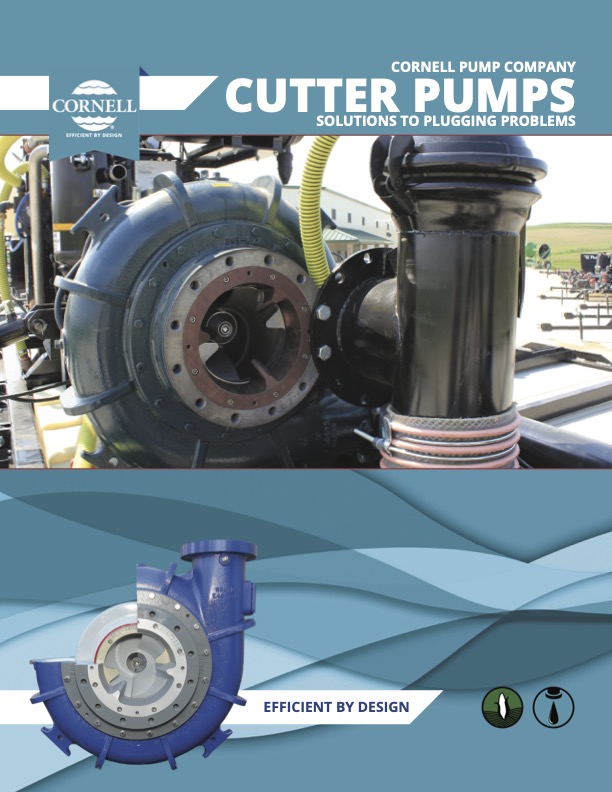

Cutters:

Cornell line of Cutter Pumps. The cutter pump was created in order to address the urgent need of reducing clogging due to ragging and roping. With the increased use of ‘flushable’ materials and extraneous cleaning products, the issue of clogging—leading to downtime, pump destruction, and pipe damage, has increased markedly. The cutters unique stationary and rotating blade design allows material to pass through the impeller that would tend to clog a non-cutter pump. The cutter is adjustable and made from special hardened metal to extended life operation. The cutter impeller can be retrofitted on existing pumps and will not change the external pump dimensions. Cornell’s cutters are offered in two versions: the standard Blade Cutter which can be fitted into virtually any existing pump model or the specially designed Waste Warrior pump models for more aggressive ragging and plugging.

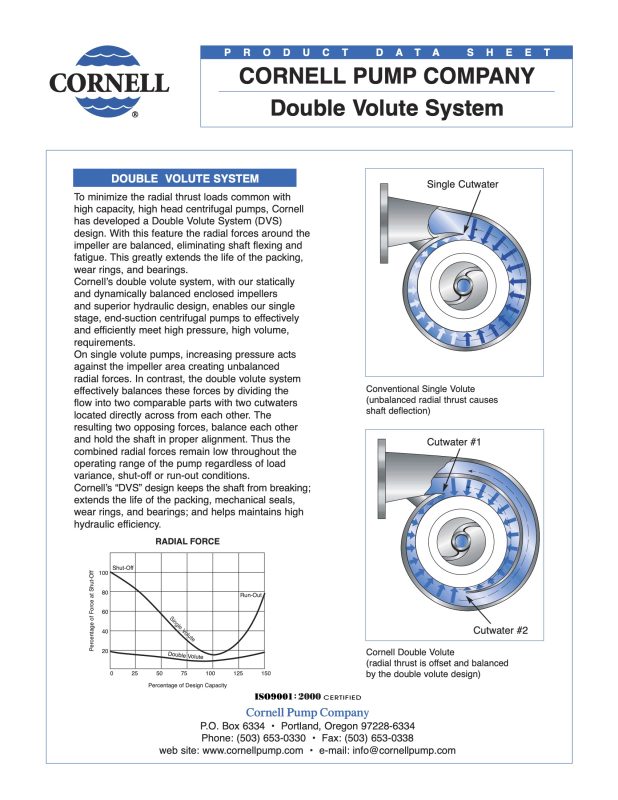

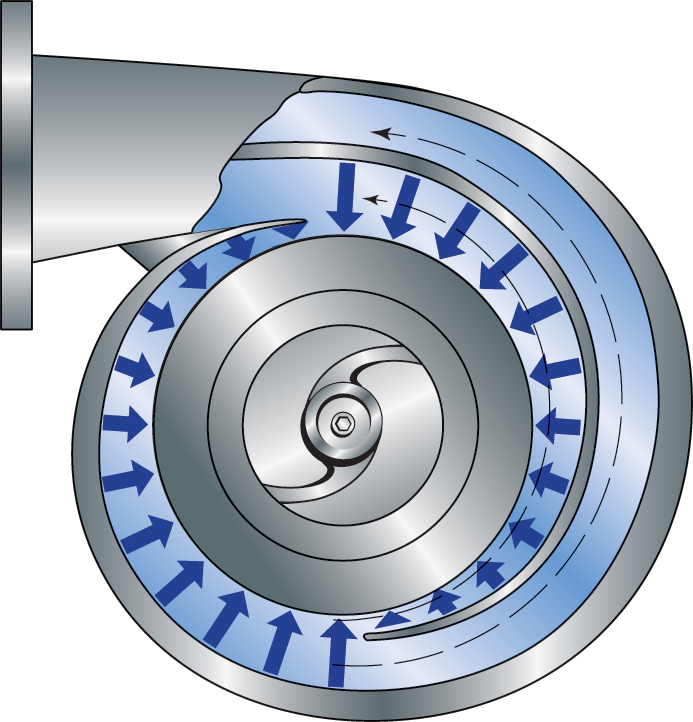

Double Volute:

The double volute system enables Cornell single-stage, end-suction centrifugal pumps to easily perform big volume and high pressure jobs. On single volute pumps, the increasing pressure acts against the impeller area and creates unbalanced radial forces. By contrast, the Double Volute System effectively balances these forces around the impeller to reduce shaft flexure and fatigue for longer seal life, bearing life, and shaft life.

Heavy-Duty Bearing Frame:

Cornell Pump Company’s distinctive frame design incorporates mounting surfaces rather than mounting feet. Look for the angular frame to know that you have a genuine Cornell frame. Cornell bearing frames are designed to support the heavy-walled castings and robust construction of Cornell pumps.

CD4MCu

CD4MCu is a duplex stainless steel, utilizing a two-phase metallurgy, compared to a single-phase metallurgy, which is used in more common grades of stainless steel, such as 316. This metallurgy process combines the corrosion resistance of 300 series stainless steel with the strength and hardness of 400 series stainless steel.

The end result is a stainless steel with corrosion resistance equal to or better and 316 SS, but with double the yield strength. CD4MCu construction allows the pumps to be used in more abrasive applications with better resistance to corrosive cracking and pitting.