- Food and beverage

- Industrial fryers

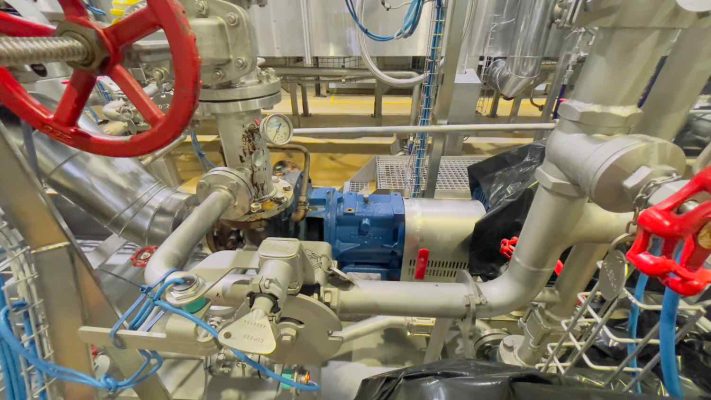

Cornell’s hot oil pump utilizes enhanced vapor handling and improved sealing technology to provide a worry-free operation. When fresh product passes through a fryer, water tends to travel along the bottom of the fryer in a liquid phase at 392°F (200°C), until it reaches the pump suction where the action of the impeller breaks up the water into smaller droplets that flash into steam. Ordinarily, entrained steam would impair the pump’s head and flow, but Cornell’s innovative anti-cavitation system prevents this situation.

Along with the anti-cavitation feature, Cornell has developed a custom cartridge seal specially designed for high temperature operations which prevents coking.

CARTRIDGE SEAL WITH QUENCH OPTION

An enhanced sealing option now available on Cornell’s hot oil pumps, the cartridge seal offers these benefits:

- Safeguard employees and plant by guarding against leaks and failures

- Enhanced seal life against coking and product build-up

- Brief periods of dry running possible because of seal design

- Installation and repairs are easy to carry out, and galling less likely on shaft

- Enhanced heat range. Seals are usable up to 450° F/ 232C

- Quench with steam or water

- Prevents solids build-up on atmospheric side of seal

- Quench pressure should be limited to 0.2 BAR (3PSI) or less

Features and Benefits

- Uniform thermal expansion

- Ductile iron and stainless-steel construction also available

- External balance line for lower seal box pressure, particle removal, and reduced axial loading

- Vapor suppression line to help eliminate flushing of water-entrained oil

- Oil-lubricated bearing frames

- Replaceable wear rings and shaft sleeves

- Fully machined impellers

- Heavy-walled castings

- Two-year warranty

- Low cost of repair

- High efficiency

- Double volute (select models)

- Metal bellows high temperature mechanical seals

- Water cooled seal seat

- All units hydrostatically tested