Cornell’s CB series of refrigeration pumps have been used successfully in a variety of applications including cold storage, food processing, refrigeration, ice production and turbine inlet cooling.

Introduced more than 50 years ago, Cornell CB Series refrigerant pumps are still commonly employed in liquid overfeed and transfer pump applications utilizing anhydrous ammonia, aqueous ammonia, and halocarbons such as R-22 and other approved refrigerants.

Specifications:

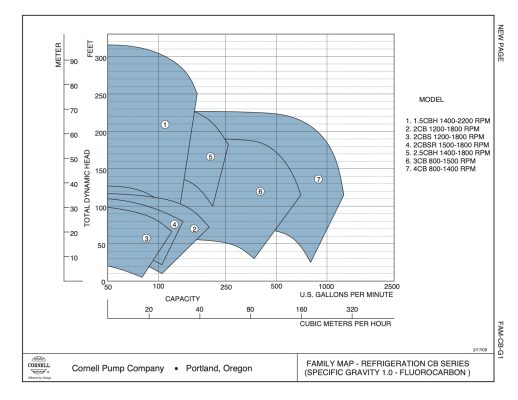

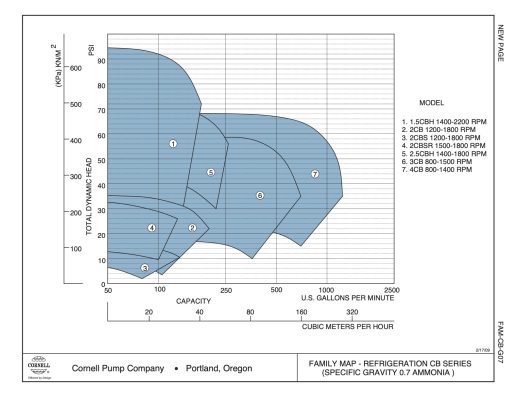

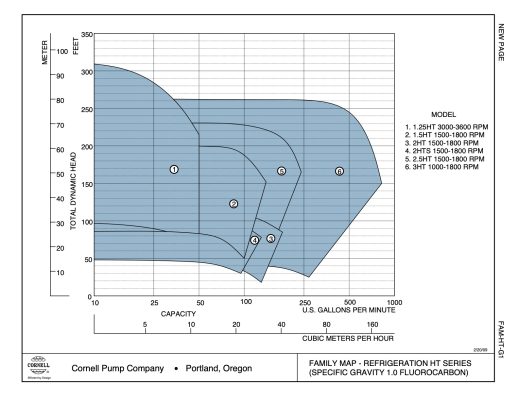

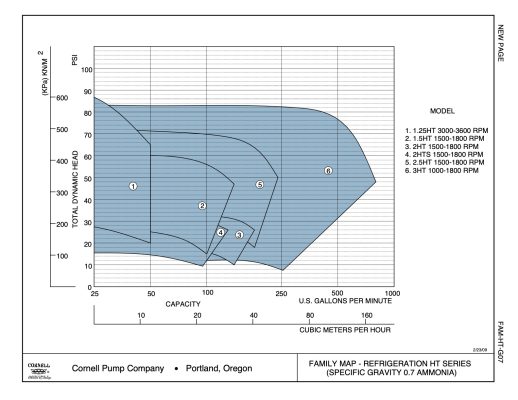

Sizes: 1.5”, 2”, 3”, and 4” discharge size

Flows up to 227 m³/h (1000 GPM)

Heads up to 91 PSI (AMMONIA) and 95 m (310 feet) (FLOUROCARBON)

Solids Diameter up to 11 mm (0.44”)

Features and Benefits

- Refrigerant Emission Free sealing technology

- Solids handling up to 3/8″

- Oil-lubricated seals do not rely on presence of pumpage

- Industry-leading three-year warranty

- 250 PSIG working pressure