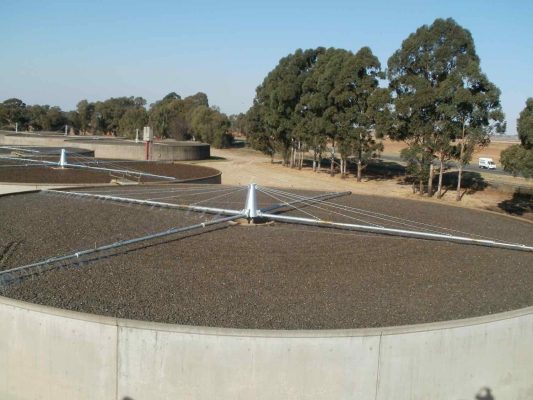

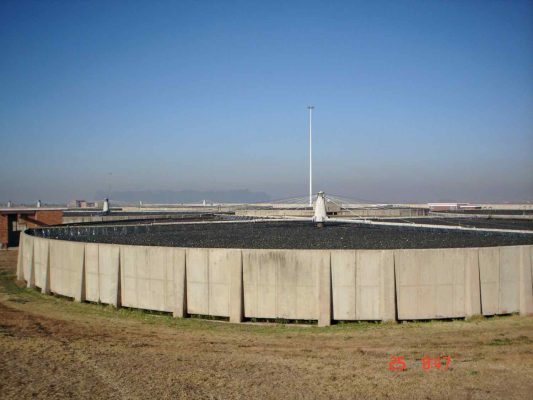

Rotary distributors are used in the biological wastewater treatment process through an application known as the trickling filter method. This procedure has good adaptability and is able to effectively handle peak shock loads. Rotary Distributors consist of a rock bed, normally 3 to 4 meters in depth, with enough space in between the rocks to allow for the unobstructed circulation of air. The effluent is sprinkled over the bed packing, which is coated with a biological slime. As the liquid trickles over the packing, oxygen and dissolved organic matter within the wastewater diffused into the film to be metabolized by the micro-organisms in this slime layer. End products, such as NO3, CO2 etc., diffuse back out of the film and appear in the filter effluent.

The unit is completely seal free and requires minimal maintenance. The implementation of an effective bio filter system allows for optimal removal of 40 to 50 % of the original suspended solids as well as the removal of nearly all original dissolved organics and in-organics left over from primary treatment.