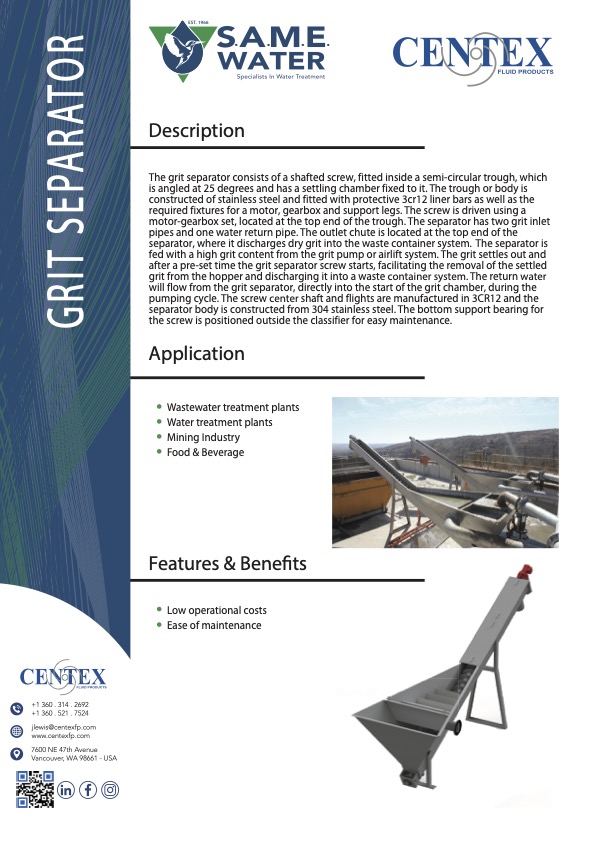

The grit separator consists of a shafted screw, fitted inside a semi-circular trough, which is angled at 25 degrees and has a settling chamber fixed to it. The trough or body is constructed of stainless steel and fitted with protective 3cr12 liner bars as well as the required fixtures for a motor, gearbox and support legs. The screw is driven using a motor-gearbox set, located at the top end of the trough. The separator has two grit inlet pipes and one water return pipe. The outlet chute is located at the top end of the separator, where it discharges dry grit into the waste container system. The separator is fed with a high grit content from the grit pump or airlift system. The grit settles out and after a pre-set time the grit separator screw starts, facilitating the removal of the settled grit from the hopper and discharging it into a waste container system. The return water will flow from the grit separator, directly into the start of the grit chamber, during the pumping cycle. The screw center shaft and flights are manufactured in 3CR12 and the separator body is constructed from 304 stainless steel. The bottom support bearing for the screw is positioned outside the classifier for easy maintenance.